A thimble should be cemented with high temperature cement into the masonry wall of the chimney and the stovepipe inserted into the thimble without cement for easy removal for cleaning and replacement.

Clay chimney thimble installation.

Clay flue liners pulls air up and expels it out of the top of the flue using draft.

Place the thimble into the hole.

Size and weights approximate.

The thimble shall protrude at least 1 4 beyond the metal base flange.

Superior clay corporation manufactures quality handcrafted clay products used in custom fireplaces wood fired ovens and other ornamental architectural products.

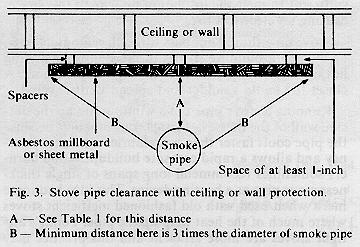

Single wall stove pipe going from the stove to the chimney must have a minimum of 18 clearance to combustibles.

Insert the thick wall thimble into the mounted metal base.

Fire clay for maximum heat resistance.

Clay flue liners enhances the chimney s performance of protection and safety to your home.

Apply a layer of stove cement to the edges of the opening using a trowel.

If the thimble protrudes more than 1 2 beyond round metal base flange into room mark thimble using flange edge as a guide.

You should pack insulation snugly against the outside box frame of the thimble but never place insulation into the area within the thimbles s cylinder.

Position thimble firmly against chimney.

Apply additional stove cement to fill any gaps and to seal the thimble securely.

Clay flue liners provides proper air flow for maximum performance.

Stabilizing the thimble with one hand press the mortar around the thimble on all sides with a trowel using the other hand.

Our products include rumford fireplace components clay chimney pots herringbone fireboxes and brick masonry bread ovens as well as a variety of other quality clay products.

180 degree heat shields are available for single wall pipe to reduce clearances to 6 for walls and 9 to the ceiling.